HOME OF 7075 ANODIZER

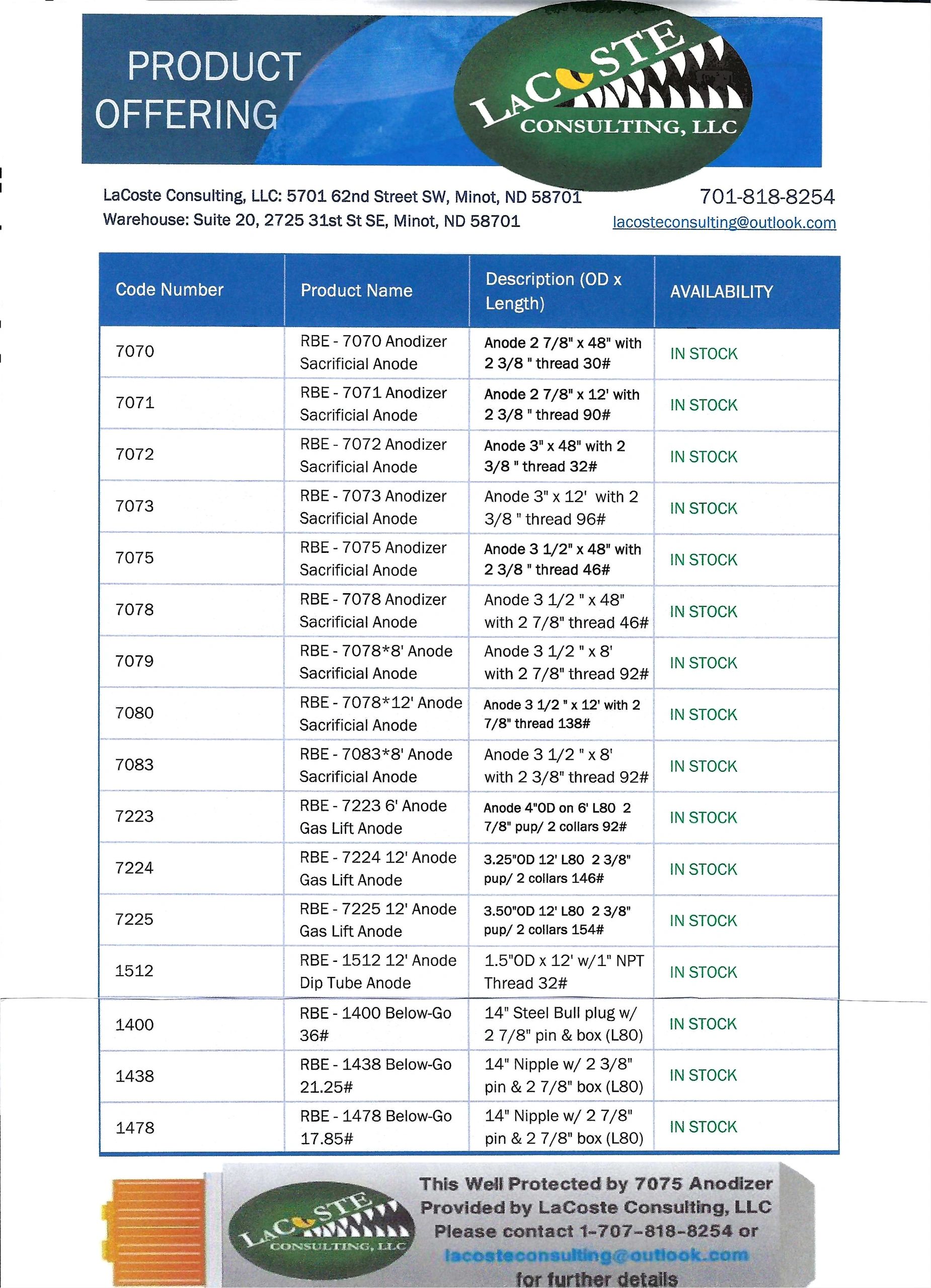

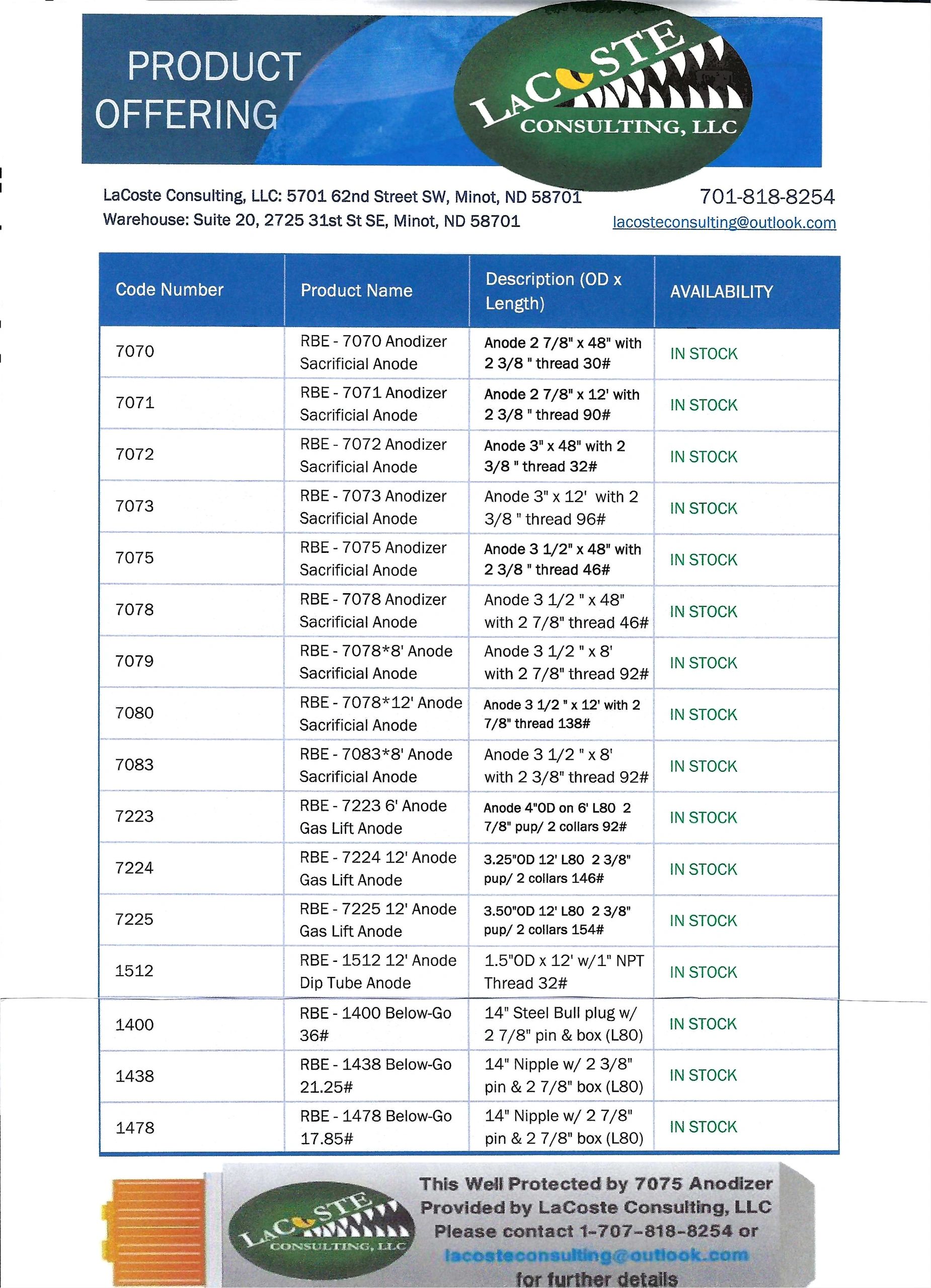

RBE 7075 Anodizer Product offering list attached.

Check out our NEW GAS LIFT ANODES in our Gallery. The new gas lift Anodes are a Revolutionary Solution for the Oil & Gas indu

Check out our NEW GAS LIFT ANODES in our Gallery. The new gas lift Anodes are a Revolutionary Solution for the Oil & Gas indu

Please reach us at lacosteconsulting@outlook.com if you cannot find an answer to your question.

Our customer shared information and pictures on Anodes that were ran 3 months ago. After looking at the pictures I asked if they had been doping the threads before installation and customer stated yes, they had doped the threads. In a 90-day run they lost 15 joints to Red Band. During our conversation I pointed out that it is recommended to NEVER dope the threads on the Anode. We want a clean and dry installation for best electrical connectivity.

Customer questioned if he could rerun his lightly used Anode that they had previously installed. I recommended they clean up the threads as good as possible and to install in a clean and dry coupling with no dope on this connection. There should be lots of life left in this Anode to protect their Rod Lift application.

Yes. We currently have 1 product in stock. Which is the RBE 7223 6' Anodizer. This is a 6' L80 pup joint with and Anode attached to the outside with a 4" OD.

Coming in December 2023 we will have 2 additional options to choose from for smaller ID wells.

The RBE 7224 will be a 12' L80 2 3/8" pup joint with an Anode OD of 3.25".

The RBE 7225 will be a 12" L80 2 3/8" pup joint with an Anode OD of 3.50".

Absolutely, you can run as many Anodes as required, above and/or below the Mandrels. It is all about protecting your assets. We've had discussions with clients who are thinking about running the RBE 7223 higher up in the string on the 2 7/8" and adding multiple RBE 7224's below the Mandrel on 2 3/8" string.

Yes. We currently have customers installing the RBE 7223 above their NoGo's in Rod Pump and ESP applications.

LaCoste Consulting LLC has a large quantity of In Stock Anodes. Our goal is to assist our customers in eliminating costly delays waiting on products.

LaCoste Consulting LLC has a large quantity of Below-Go's in Stock. We have received feedback from customers where Anodes had cut through attache below No-Go's, caused by aggressive swirl under the No-Go. the Below-Go 14" Nipples prevents the Anode from premature failure due to aggressive swirl below the larger No-Go.

We were approached by Clients in 2023 about an every going problem in the gas lift market. Requesting our assistance in finding a solution. We designed several varieties of Sacrificial Anodes that will provide corrosion protection in these extreme applications.

RBE 7223 is our first in a series of revolutionary solutions combating corrosion in downhole applications. Designed for gas lift but used in multi applications.

If you are looking for solutions in small casings and liners. We know have a product 2 3/8" tubing with 3.25" OD Anode at 12' long. Providing protection where chemicals may not be available.

RBE 7225 provides 3.50" OD x 12' long Anode. Running multiple Anodes throughout the String if required.

At LaCoste Consulting, LLC, our mission is to provide high-quality oil and gas services to our clients while minimizing environmental impact and promoting safety.

With over 20 years of experience in the industry, our team has the expertise to handle any oil and gas project, from exploration to production.

Safety is our top priority at LaCoste Consulting, LLC. We maintain strict safety protocols and provide our team with ongoing training to ensure that every project is completed safely.

Taking on a high H2S / CO2 injected well in Central Alberta. Equipment came out in GREAT shape, customer pleased with the protection they received from the RBE 7075 Anodizer.

NO chemical was used in this application.

RBE 7075 took on the Well & did the job it is designed to do.

Customer Testimony:

"I have attached a picture of your anode that was in one of our ESP production CO2 EOR wells that was in the hole for 6 months. Looks like it did its job."

"There were no signs of corrosion on the pump at all, and they did not add any corrosion inhibitor at all during the time it ran."

Installing a 7075 ANODIZER will protect your Down Hole tubing & equipment from premature failure due to corrosion. Sacrificial anode

We are hoping 2021 is a better year for everyone, LaCoste Consulting LLC is seeing an increase in activity. We appreciate all the enquiries and the growing list of new clients that are interested in extending the life of their downhole equipment and tubing with our Anode's. If you are looking for a simple cost effective solution to protect your investment, and eliminate premature failures please don't hesitate to contact LaCoste Consulting LLC.

#7075anodizer

This customer installed the Anode 8-17-2020. Unfortunately the ESP motor was compromised by a protector break down.

There was no physical damage to the cable, pumping equipment or the tubing.

The Anode looks beautiful and it did exactly what it is designed to do.

The RBE 7075 Anodizer lived up to it's name the Red Band Eliminator.

#7075anodizer

We purchased this Sacrificial Anode back after a well had been fracked into. The video shows how the corrosion starts attacking the Sacrificial Anode immediately. The Sacrificial Anode was only in the well for three weeks prior to being fracked into.

We got you covered.

Side by Side sacrificial anode comparison - New 7075 Anodizer & Used 7075 Anodizer Customer equipment & tubing in pristine shape due the galvanic corrosion attacking the cathode

This well was pulled to downsize the ESP. The ESP and tubing was reported to have no corrosion. This picture shows what remains of the sacrificial anode at 422 days. The anode still had plenty of life.

Sacrificial anode standard size for ESP / Insert Pump or Salt Water Disposal applications

Standardized for each application

WHAT IS CORROSION?

There are many different types of corrosion, each of which can be classified by the cause of the metal's chemical deterioration.

Common types of corrosion:

General Attack Corrosion:

Also known as uniform attack corrosion, general attack corrosion is the most common type of corrosion and is caused by a chemical or electrochemical reaction that results in the deterioration of the entire exposed surface of a metal. Ultimately, the metal deteriorates to the point of failure.

General attack corrosion accounts for the greatest amount of metal destruction by corrosion but is considered as a safe form of corrosion, since it is predictable, manageable and often preventable.

Localized Corrosion:

Unlike general attack corrosion, localized corrosion specifically targets one area of the metal structure. Localized corrosion is classified as one of three types:

Galvanic Corrosion:

Galvanic corrosion or dissimilar metal corrosion occurs when two different metals are located together in a corrosive electrolyte. A galvanic couple forms between the two metals, where one metal becomes the anode and the other the cathode. The anode or sacrificial metal corrodes and deteriorates faster than it would alone, while the cathode deteriorates more slowly than it would otherwise.

Three conditions must exist for galvanic corrosion to occur:

Environmental Cracking:

Environmental cracking is a corrosion process that can result from a combination of environmental conditions affecting the metal. Chemical, temperature and stress-related conditions can result in the following types of environmental corrosion:

Flow-Assisted Corrosion (FAC):

Flow-assisted corrosion or flow-accelerated corrosion results when a protective layer of oxide on a metal surface is dissolved or removed by water thus exposing the underlying metal to further corrosion and deterioration.

Intergranular Corrosion

Intergranular corrosion is a chemical or electrochemical attack on the grain boundaries of a metal. It often occurs due to impurities in the metal which tend to be present in higher concentration near grain boundaries. These boundaries can be more vulnerable to corrosion than the bulk of the metal.

De-Alloying:

De-alloying or selective leaching is the selective corrosion of a specific element in an alloy. The most common type of de-alloying is de-zincification of unstable brass. The result of corrosion in such cases is a deteriorated and porous copper.

Fretting Corrosion:

Fretting corrosion occurs as a result of repeated wearing, weight and/or vibration on an uneven, rough surface. Corrosion, resulting in pits and grooves, occurs on the surface. Fretting corrosion is often found in rotation and impact machinery, bolted assemblies and bearings, as well as to surfaces exposed to vibration during transportation.

High-Temperature Corrosion:

Fuels used in gas turbines, diesel engines and other machinery which contain vanadium or sulfates. Can, during combustion, form compounds with a low melting point. These compounds are very corrosive towards metal alloys normally resistant to high temperatures and corrosion, including stainless steel.

High-temperature corrosion can also be caused by high-temperature oxidization, sulfidation, and carbonization.

Reference:

Bell, Terence. "What is Corrosion?" Thought Co, Oct. 29, 2020, thoughtco.com/types-of-corrosion-2340005.

Customer did not lose any tubing due to corrosion.

The beauty of the 7075 Anodizer is within. - Like a fine wine the Anode gets better with time.

To align with our customers needs, LaCoste Consulting has designed and manufactured a 3 inch diameter sacrificial anode for applications where the RBE 7072 Anodizer is a better choice. In stock as of 5-24-2021. Please contact us today so we can assist you with your applications.

To align with our customers needs, LaCoste Consulting has designed and manufactured a 3 1/2 inch diameter with 2 7/8 inch EUE sacrificial anode for applications where the RBE 7078 Anodizer is a better choice. In stock as of 9-1-2021. Please contact us today so we can assist you with your applications.

1-1-2021 Plane Rigging

Please contact us for our 7075 sacrificial anode pricing & shipping. Will ship anywhere in North America. Made in USA.

1-701-818-8254

1-701-509-4044

5701 62nd Street SW, Minot, ND 58701-2702

Calvin LaCoste has over 30 years of oilfield experience working for you.

Copyright © 2025 LaCoste Consulting, LLC - All Rights Reserved.